We completed the relocation of the new factory on March 15, 2021.

In addition to relocating to the new factory, we plan to implement standard 5S management in the next two to three years to bring customers better services, more advantageous prices, and higher quality products.

5S on-site management method, modern enterprise management mode, 5S is sorting (SEIRI), rectifying (SEITON), cleaning (SEISO), neat (SEIKETSU), literacy (SHITSUKE), also known as the "Five Constant Principles.

The best utility of 5S management can be summarized into 5 Ss, namely safety, sales, standardization, satisfaction (customer satisfaction), and saving.

1. Ensure safety (Safety)

By implementing 5S, companies can often avoid fires or slips caused by oil leakage; various accidents and failures caused by non-compliance with safety rules; pollution caused by dust or oil pollution, etc. Therefore, production safety can be implemented.

2. Expand sales (Sales)

5S is a very good salesman who has a clean, tidy, safe and comfortable environment; a company with a well-qualified workforce often wins the trust of customers.

3. Standardization

Through the implementation of 5S, the habit of observing standards is cultivated within the enterprise, so that all activities and operations are run in accordance with the requirements of the standards, and the results are in line with the planned arrangements, laying the foundation for providing stable quality.

4. Customer Satisfaction (Satisfaction)

Impurities such as dust, hair, oil, etc. often reduce the processing precision and even directly affect the quality of the product. After the implementation of 5S, cleaning and cleaning are guaranteed, and the product is formed, stored, and delivered to customers in a good hygienic environment, and the quality is stable.

5. Saving

Through the implementation of 5S, on the one hand, the auxiliary time of production is reduced and work efficiency is improved; on the other hand, the failure rate of equipment is reduced, and the efficiency of equipment use is improved, thereby reducing certain production costs.

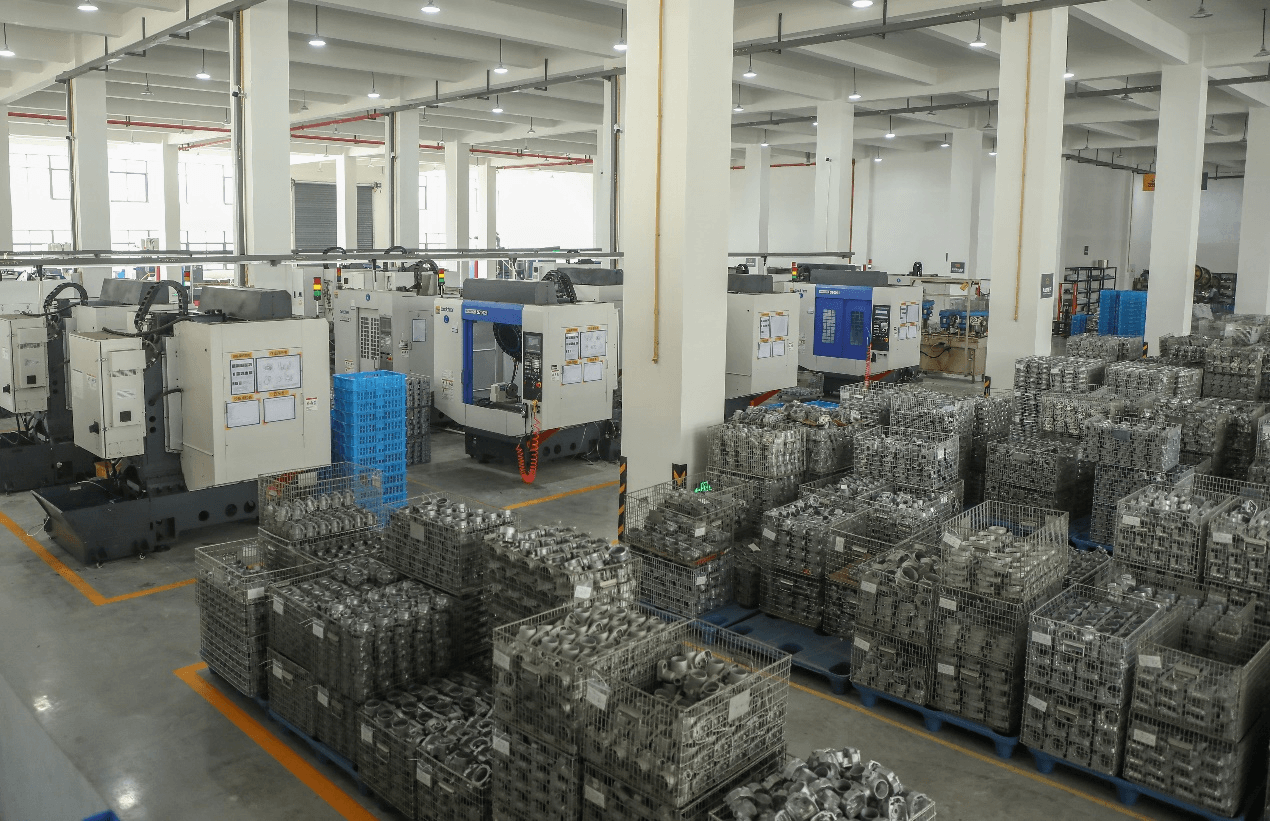

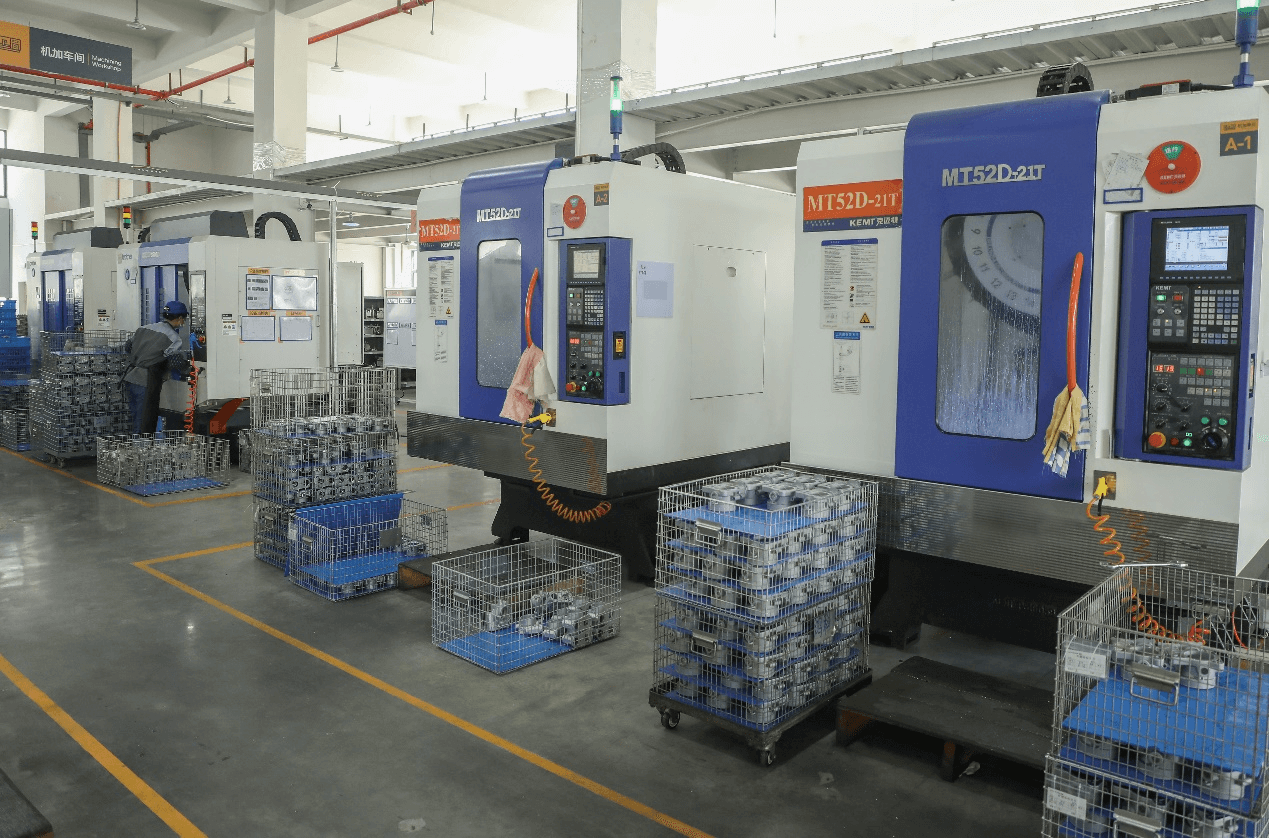

Machine Shop

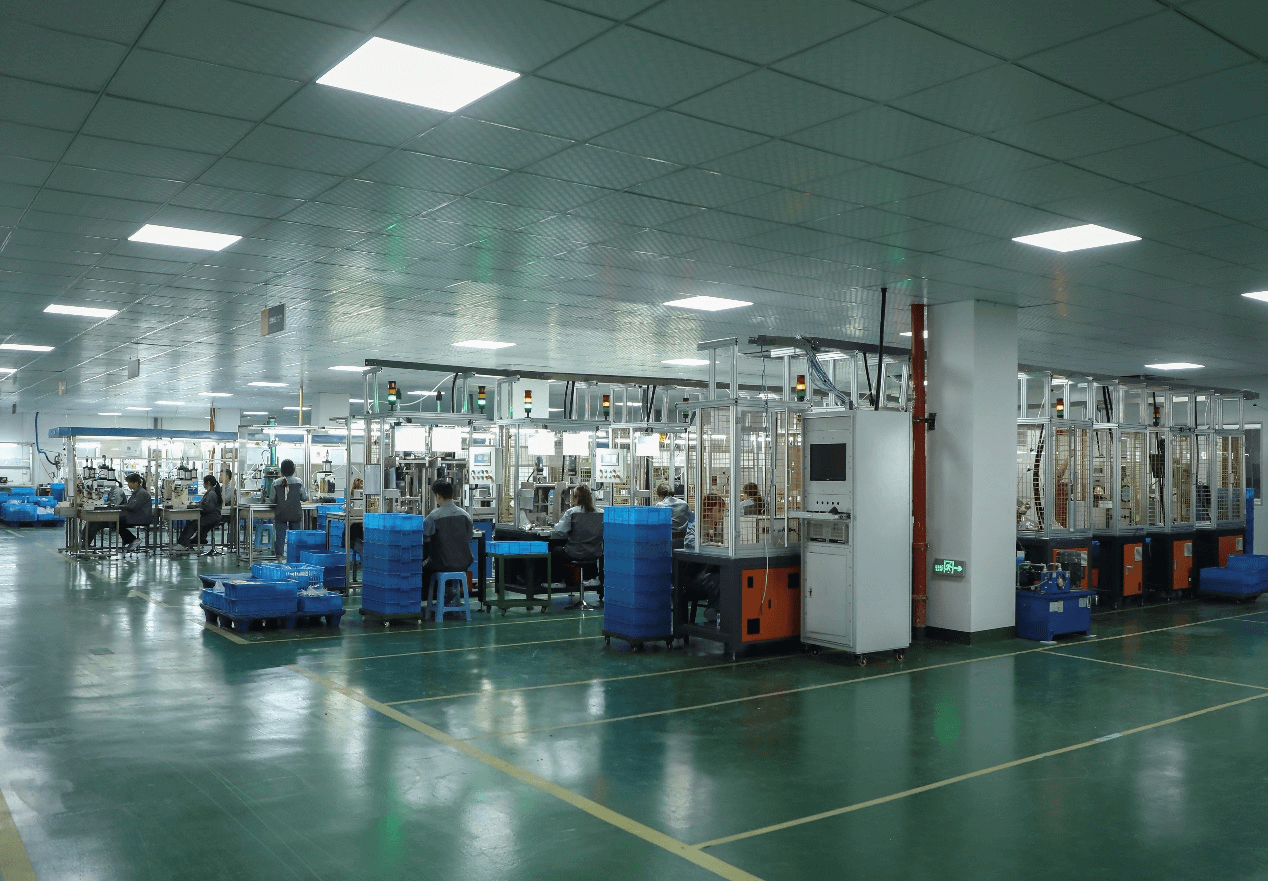

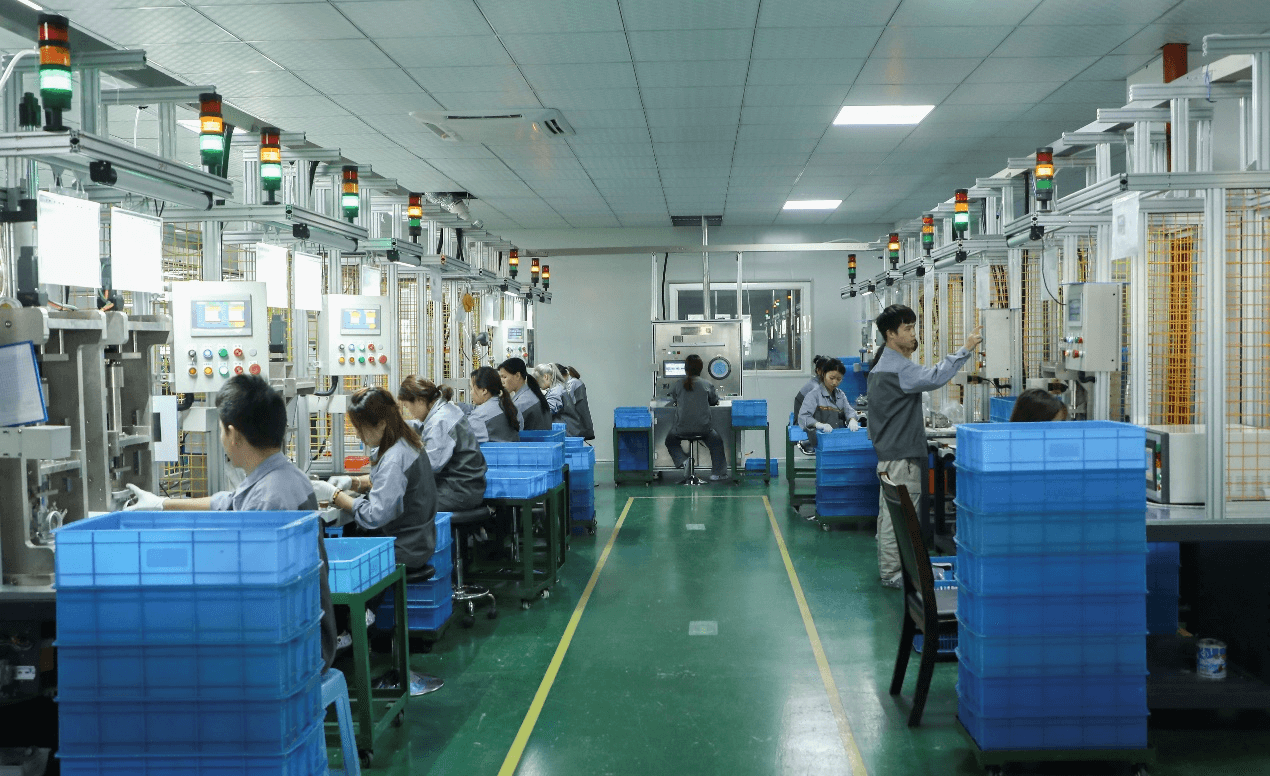

Assembly Workshop

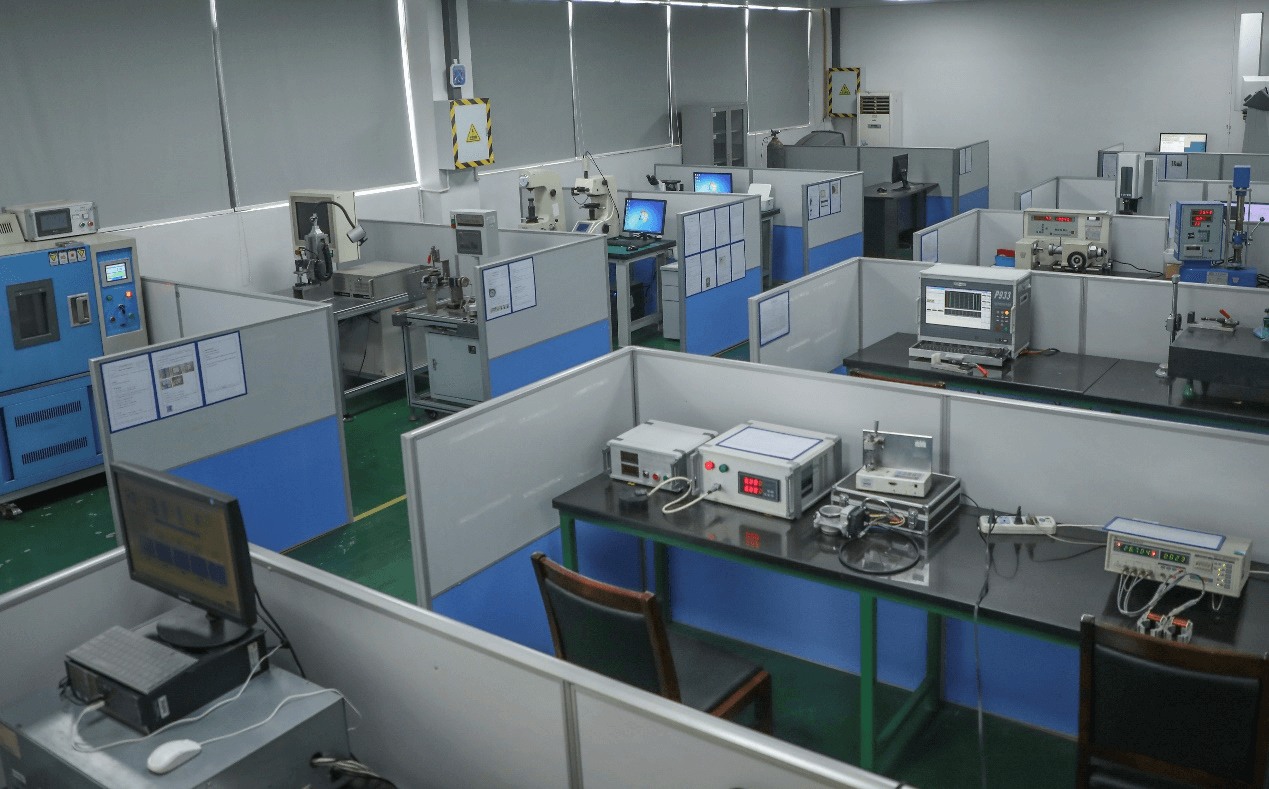

Laboratory

Parts Warehouse

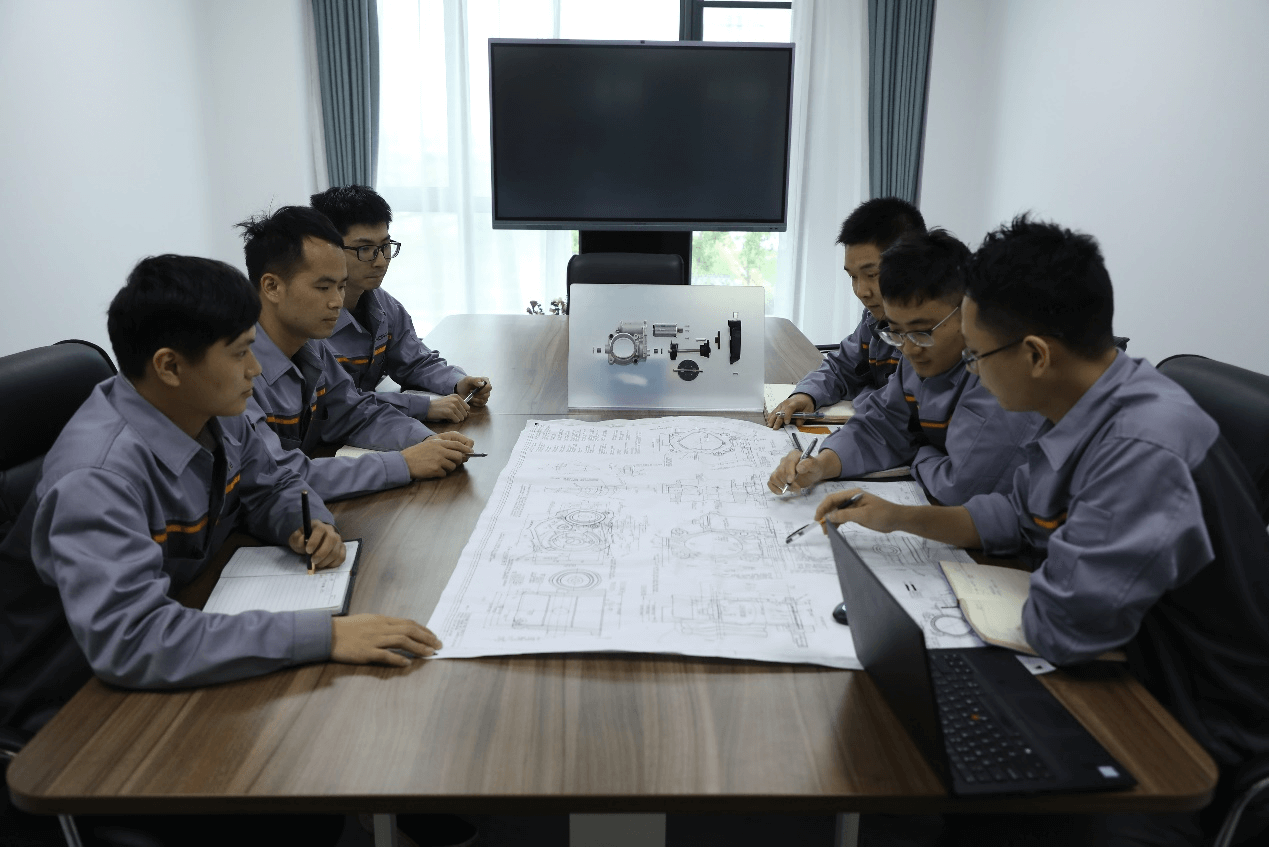

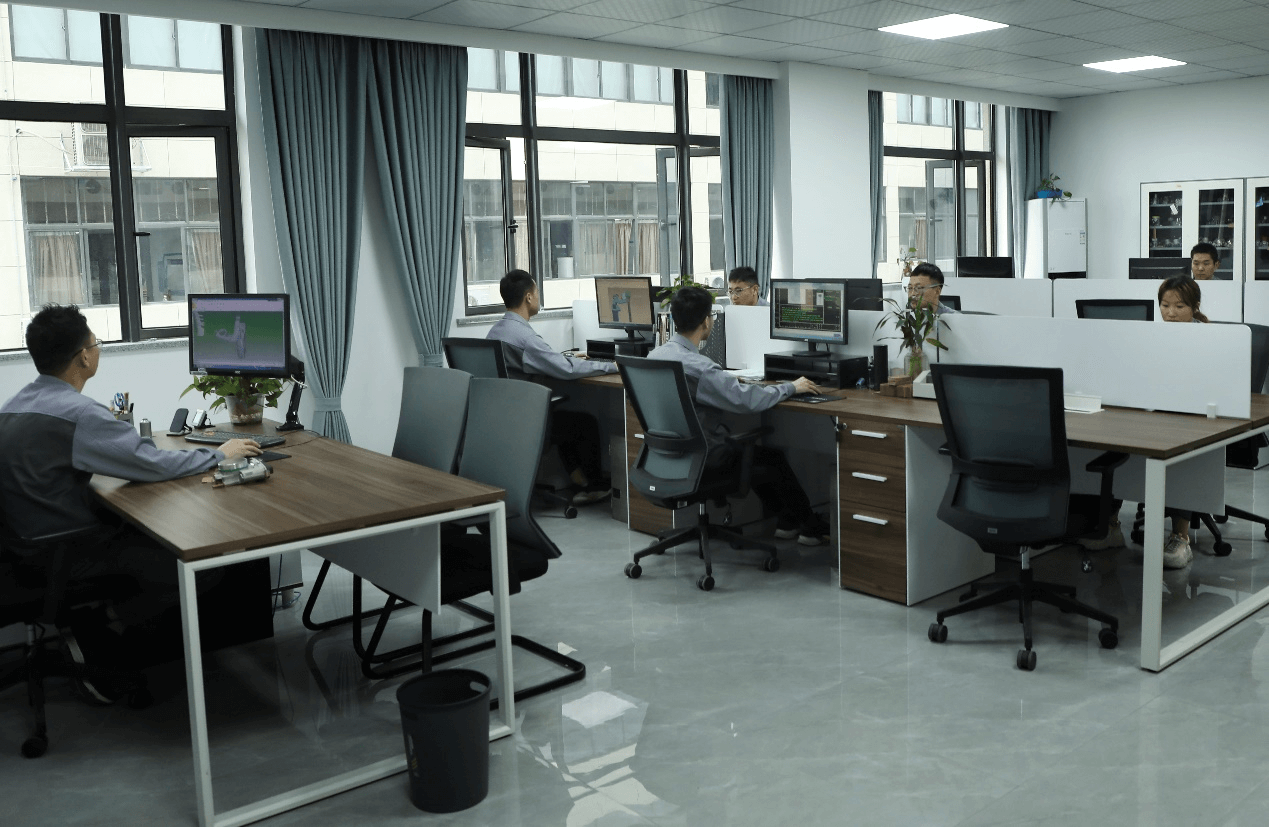

Conference Room and Technical Office

Post time: Dec-03-2021